This week I taught a two-day course on behalf of the Centre for Leadership and Learning in the Ontario Public Service (OPS). It’s called “Management Essentials,” and is for non-managers who want to either learn more about how management is expected to perform within the values and objectives of the OPS, or to understand what it takes to become a manager – thus being able to assess their own skills gaps and build them up accordingly.

This week I taught a two-day course on behalf of the Centre for Leadership and Learning in the Ontario Public Service (OPS). It’s called “Management Essentials,” and is for non-managers who want to either learn more about how management is expected to perform within the values and objectives of the OPS, or to understand what it takes to become a manager – thus being able to assess their own skills gaps and build them up accordingly.

This is a great course, and I enjoy teaching it so much not only because the materials are current and relevant, but because the people who attend generally WANT to be there (vs. being “told” to take a course in presentation skills, or “how to write a briefing note”). Teachers reading this will agree that when people attend because they want to, they are generally much more engaged and the class has more energy.

This was true this week – a great class filled with 35 interesting people from many different areas of the OPS, with differing levels of experience and terrific stories to bring life to the material.

As I drove home I reflected on a couple of standout things that I learned from the class, and thought I’d share them with you in this week’s blog:

One: We need to remind people, over and over again, that THEY are responsible for their careers and their professional development.

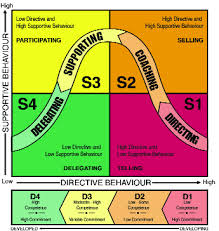

Situational Leadership Model

One of the conversations we had (a couple of times) relates to the last blog post I wrote (Does Your Manager Like People). We had just finished discussion on the Situational Leadership model of applying directive vs. supportive leadership techniques. This tool is a BIG hit with people – while complex at first, it is extremely helpful for new managers when they need to accept and learn that their natural, or comfortable, style of learning may not be appropriate in all situations. It helps them assess, adapt, and communicate in a more effective way.

A student approached me at the break and said, “this is AMAZING. I think my manager missed this subject when she was promoted and attended manager training.”

“Ah, bless your heart,” I thought.

I made sure to share with the class that in most organizations, there is no training to become a manager. (As an aside, I may enjoy a little too much dropping those bombs and watching the reactions.) The conversation that followed was an important one, as people realized that it is up to them to learn how to be a good leader.

A great manager should be encouraging their teams to learn and grow, develop career goals and job shadow, take courses, or broaden their perspectives. In the absence of a great manager, many people flounder and future talent may be lost.

Two: There are employees out there who want to innovate, change, and improve, and we need to find and harness that energy more effectively.

After the “manager training is up to you” conversation, there was a slight shift in energy, with more questions aimed at the application of the course material in a practical way to help people apply for and win new jobs.

One question came from a young man who likes his job very much, has been with the OPS for about five or six years with no complaints, and who is starting to feel frustrated. “I’m naturally inquisitive and process-oriented. I see people do the same things over and over with the same results, but no one takes the time to stop and fix the process so that things improve. Where are all the process jobs???”

Not an easy question to answer. Of course there are process jobs out there, and within the Ontario Government there are specific areas that are more process-focused than others. The trick is in finding those job descriptions and being able to read between the lines and know that certain phrases indicate a culture of process improvement more than others.

The real key is meeting the right people. This student was taking control and doing the right things – taking courses, asking questions, discussing his goals and dream job criteria with people, and being open to new opportunities. By doing so, he was exposing himself to more people who might be able to point him in the right direction.

I’d love to see the process-focused culture shift happen more quickly – not only in the OPS but in other private-sector organizations as well. Imagine if more job descriptions included a requirement for some type of Innovation Thinking, or the ability to demonstrate a process-improvement focus as part of regular job functions.

I may be biased, but I think that a process focus culture is the next big thing required in business today. If we could find these naturally process-oriented people and maximize their energy, we could shift our thinking from “process improvement or day job” to “day job through process improvement.” (Click to Tweet)

I teach again in a couple of weeks… can’t wait to see what my students teach me then!!

Until next time,

Ruth.